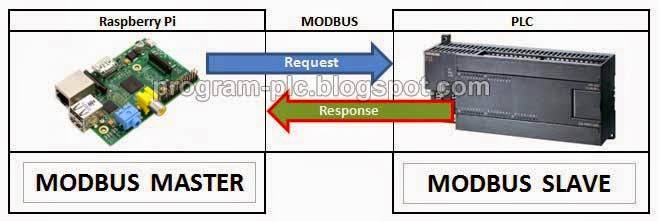

Modbus communication in these applications using serial communication / RS232 and Modbus RTU.

This application use simple modbus with Python programming on Raspberry Pi, and not use modbus from a third party.

For the hardware used in this application:

1. PLC

2. Raspberry Pi (Only for setting, using: monitor, keyboard, mouse, adapter, flash disk)

3. Serial PLC Cable

4.Serial Module ,and

5. Serial Crossover Connector.

For the connection beetween PLC and Raspberry Pi, Raspberry Pi Setting

(Auto Login, Install PySerial, Setup UART Pins, Auto Run Python after

Booting) :

Connection of Modbus RTU Communication Between PLC and Raspberry Pi:

About Modbus:

Modbus application using function code 03, and function code 16. for this function code, you can go to the link:

http://program-plc.blogspot.com/2014/09/how-to-make-simple-modbus-rtu.html

Python Code of Modbus Communication on Raspberry Pi:

import serial

import random

#Sub Program

#CRC

Calculation

def CRCcal(msg):

#CRC (Cyclical Redundancy Check)

Calculation

CRC = 0xFFFF

CRCHi = 0xFF

CRCLo = 0xFF

CRCLSB = 0x00

for i in range(0,

len(msg)-2,+1):

CRC = (CRC ^ msg[i])

for j in range(0,

8):

CRCLSB = (CRC & 0x0001);

CRC = ((CRC >> 1) &

0x7FFF)

if (CRCLSB == 1):

CRC = (CRC ^ 0xA001)

CRCHi = ((CRC >> 8) & 0xFF)

CRCLo = (CRC & 0xFF)

return (CRCLo,CRCHi)

#CRC Valdation

def CRCvalid(resp):

CRC = CRCcal(resp)

if (CRC[0]==resp[len(resp)-2])

& (CRC[1]==resp[len(resp)-1]):return True

return False

#Modbus

Function Code 16 = Preset Multiple Registers

def Func16Modbus(slave,start,values):

Slave_Address = slave

Function = 16

Starting_Address = start

NumberofRegisters = len(values)

Byte_Count = NumberofRegisters * 2

message = [0 for i in range(9 + 2 * NumberofRegisters)]

#index0 = Slave

Address

message[0] = (Slave_Address & 0xFF)

#index1 = Function

message[1] = (Function & 0xFF)

#index2 = Starting Address Hi

message[2] = ((Starting_Address >> 8)

& 0xFF)

#index3 = Starting Address Lo

message[3] = (Starting_Address & 0xFF)

#index4 = Number of Registers Hi

message[4] = ((NumberofRegisters >>

8) & 0xFF)

#index5 = Number of Registers Lo

message[5] = (NumberofRegisters & 0xFF)

#index6 = Byte Count

message[6] = (Byte_Count & 0xFF)

for i in range(0,

NumberofRegisters):

#Data Hi, index7 and index9

message[7 + 2 * i] = ((values[i]

>> 8) & 0xFF)

#Data Lo, index8 and index10

message[8 + 2 * i] = values[i] &

0xFF

#CRC (Cyclical

Redundancy Check) Calculation

CRC = CRCcal(message)

#index11= CRC Lo

message[len(message)

- 2] = CRC[0]#CRCLo

#index12 = CRC Hi

message[len(message)

- 1] = CRC[1]#CRCHi

if ser.isOpen:

ser.write("".join(chr(h)

for

h in

message))

reading = ser.read(8)

response = [0 for i in range(len(reading))]

for i in range(0,

len(reading)):

response[i] = ord(reading[i])

if len(response)==8:

CRCok = CRCvalid(response)

if CRCok &

(response[0]==slave) & (response[1]==Function):return True

return False

#Modbus

Function Code 03 = Read Holding Registers

def Func03Modbus(slave,start,NumOfPoints):

#Function 3 request is always 8 bytes

message = [0 for i in range(8)]

Slave_Address = slave

Function = 3

Starting_Address = start

Number_of_Points = NumOfPoints

#index0 = Slave

Address

message[0] = Slave_Address

#index1 = Function

message[1] = Function

#index2 = Starting Address Hi

message[2] = ((Starting_Address >>

8)& 0xFF)

#index3 = Starting Address Lo

message[3] = (Starting_Address& 0xFF)

#index4 = Number of Points Hi

message[4] = ((Number_of_Points >>

8)& 0xFF)

#index5 = Number of Points Lo

message[5] = (Number_of_Points& 0xFF)

#CRC (Cyclical Redundancy Check)

Calculation

CRC = CRCcal(message)

#index6= CRC Lo

message[len(message)

- 2] = CRC[0]#CRCLo

#index7 = CRC Hi

message[len(message)

- 1] = CRC[1]#CRCHi

if ser.isOpen:

ser.write("".join(chr(h)

for

h in message))

responseFunc3total = 5 + 2 *

Number_of_Points

reading = ser.read(responseFunc3total)

response = [0 for i in range(len(reading))]

for i in range(0,

len(reading)):

response[i] = ord(reading[i])

if len(response)==responseFunc3total:

CRCok = CRCvalid(response)

if CRCok &

(response[0]==slave) & (response[1]==Function):

#Byte Count in index 3 =

responseFunc3[2]

#Number of Registers = byte

count / 2 = responseFunc3[2] / 2

registers = ((response[2] /

2)& 0xFF)

values = [0 for i in

range(registers)]

for i in range(0, len(values)):

#Data Hi and Registers1

from Index3

values[i] = response[2 * i

+ 3]

#Move to Hi

values[i] <<= 8

#Data Lo and Registers1

from Index4

values[i] += response[2 * i

+ 4]

negatif =

values[i]>>15

if

negatif==1:values[i]=values[i]*-1

return values

return ()

#Main Program

#Serial Port

9600,8,E,1

#Serial Open

try:

ser = serial.Serial(

port = '/dev/ttyAMA0',

baudrate = 9600,

bytesize = serial.EIGHTBITS,

parity = serial.PARITY_EVEN,

stopbits = serial.STOPBITS_ONE,

timeout = 0.2

)

except Exception, e:

raise ValueError(e)

print "START"

while 1:

#Serial Open Check

if not ser.isOpen:ser.open()

#Read of Registers

Func03ArrayValue = Func03Modbus(1,0,2);#slave,start,number of registers

if len(Func03ArrayValue)>0:

for i in range(0,

len(Func03ArrayValue)):

print "Read of Registers" + str(i) + " = " + str(Func03ArrayValue[i])

#Fill Random Value for Write

totalvalue=2

val = [0 for i in range(totalvalue)]

for i in range(0,

len(val)):

val[i] = random.randrange(-32767,32767)

#Random Valiue from -32767 to max 32767

#Write of Registers

WriteValid =

Func16Modbus(1,2,val)#slave,start,array value

if WriteValid:

for i in range(0,

len(val)):

print "Write of Registers" + str(i) + " = " + str(val[i])

print "#################################"