.

.

.

.

USER:

NO CONTACT

NC CONTACT

LOAD

LATCH COIL

UN LATCH COIL

BIT:

1.ONE SHOT

2.ONE SHOT RISING

3.ONE SHOT FALLING

1.ONE SHOT:

It produces it pulse during off state to on state. It does not have output bit

ONE SHOT RISING:

It produces its pulse during of state to on state.

ONE SHOT FALLING:

It produces its output pulse during on state to off state

Timer and Counter Instructions

If You Want to: Use This Instruction:

Delay turning on an output TON

Delay turning off an output TOF

Time an event retentively RTO

Count up CTU

Count down CTD

Reset the accumulated value

and status bits of a timer or

counter.(Not used with

TOF timers.) RES

COMPARE INSTRUCTION:

If You Want to Use This Instruction

Test whether two values are equal (=) EQU

Test whether one value is not equal

to a second value (><) NEQ

Test whether one value is less than

a second value (<) LES

Test whether one value is less than

or equal to a second value (<=) LEQ

Test whether one value is greater

than a second value (>) GRT

Test whether one value is greater

than or equal to a second value (=>) GEQ

Test portions of two values to see

whether they are equal MEQ

Test whether one value is within the

limit range of two other values LIM

COMPUTE / MATH:

If You Want to Use This Instruction

Add two values ADD

Subtract two values SUB

Multiply one value by another MUL

Divide one value by another DIV

Change the sign of the source

value and place it in thedestination NEG

If You Want to Use This Instruction

Set all bits of a word to zero CLR

Convert an integer value to BCD TOD

Convert a BCD value to an integer

value FRD

SQUARE ROOT (SQR):

Find the square root of a value

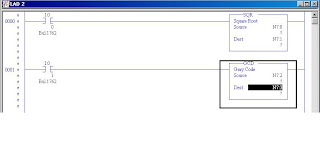

GRAY CODED DECIMAL(GCD):

This

output instruction converts the Gray code Source to integer and places

it in the Destination. On a True rung, this instruction sets the value

of the Destination to the integer value corresponding to the Gray code

Source. If the Gray code input is negative (high bit set), the

destination is set to 32767 and the overflow flag is set. The GCD

instruction only operates on Word operands.

MOVE / LOGICAL INSTRUCTION:

If You Want to Use This Instruction

Move the source value to the destination MOV

Move data from a source location to a

selected portion of the destination MVM

Perform an AND operation AND

Perform an inclusive OR operation OR

Perform an Exclusive Or operation XOR

Perform a NOT operation NOT

MOVE:

When

rung conditions preceding this instruction are true, the MOV

instruction moves a copy of the source to the destination each scan. The

original value remains intact and unchanged in its source location.

MASKED MOVE:

When

rung conditions are true, the MVM instruction moves data from a source

location to a destination, and allows portions of the destination data

to be masked by a separate word. Data at the source address passes

through the mask to the destination address. As long as the rung remains

true, the instruction moves the same data each scan.

CLEAR:

When

rung conditions are true, this output instruction sets all the bits in a

word to zero. The destination must be a word address.

AND: When rung conditions are true, sources

A and B of this output instruction are ANDed bit by bit and stored in

the destination.

PROGRAM CONTROL:

If You Want to Use This Instruction

Jump forward/backward to a

corresponding label instruction JMP, LBL

Jump to a designated subroutine and return JSR, SBR, RET

Enable or inhibit a master control zone

in your ladder program MCR

Truncate program scan TND

JUMP:

When the

rung condition for this output instruction is true, the processor jumps

forward or backward to the corresponding label instruction (LBL) and

resumes program execution at the label. More than one JMP instruction

can jump to the same label. Jumping forward to a label saves program

scan time by omitting a program segment until needed. Jumping backward

lets the controller execute program segments repeatedly.

JUMP TO SUBROUTINE:

When

rung conditions are true for this output instruction, it causes the

processor to jump to the targeted subroutine file. You can only jump to

the first instruction in a subroutine. Each subroutine must have a

unique file number (decimal, 3-255).

SUBROUTINE PAGE:

TO CREATE THE NEW SUBROUTINE PAGE:

PROGRAM FILES – RIGHT CLICK NEW

TEMPORARILY END (TND):

Use

this instruction to progressively debug a program, or conditionally

omit the balance of your current program file or subroutines.

MASTER CONTROL RESET (MCR):

An

input instruction is programmed on the rung of the first MCR to control

rung logic continuity. When the rung goes "false" all non-retentive

outputs within the controlled zone are disabled. When the rung goes

"true" all rungs are scanned according to their normal rung conditions

(disregarding the zone control instruction).

ADVANCED MATH INSTRUCTION:

If You Want to: Use This Instruction:

Swap the low and high bytes

of a specified number of words SWP

Scale a value to a range determined

by creating a linear relationship SCP

Calculate the absolute value of a number ABS

Decoder functions DCD

Encoder function ENC

DECODER(DCD):

When

rung conditions are true, the DCD instruction decodes a 4-bit value

(0-16) in the source word and turns on a bit in the destination word

that corresponds to the decoded value. For example, if bits 0-3 of a

source word are 0110, then bit 6 in the destination word is set. The

table below provides full details.

ENCODER (ENC):

This

output instruction searches the source from the lowest to the highest

bit and looks for the first set bit. The corresponding bit position is

written to the destination as an integer.

SCALE WITH PARAMETER(SCL):

This

output instruction consists of six parameters. Parameters may be

integer, long, floating point (Floating point is only supported in the

SLC 5/03, 5/04, and 5/05; not in the MicroLogix 1200 and 1500

processors.), or immediate data values or addresses containing values.

The Input value is scaled to a range determined by creating a linear

relationship between input min and max values and scaled min and max

values. The scaled result is returned to the address indicated by the

output parameter.

SWAP (SWP):

Use

the swap instruction to swap the low and high bytes of a specified

number of words in a bit, integer, ASCII, or string file. The

instruction consists of two parameters, a source and a length.

ABSOLUTE VALUE (ABS):

This

output instruction consists of two parameters, a source and a

destination. When enabled it calculates the absolute value of the source

and places the result in the destination.

Source can be a word address, an integer constant, floating point data element, or floating point constant.