QUICK FACTS

- NAME

- R.K. Narayan

- OCCUPATION

- Author, Journalist

- BIRTH DATE

- October 10, 1906

- EDUCATION

- Maharaja College of Mysore

- ORIGINALLY

- Rasipuram Krishnaswami Iyer Narayanaswami

- R. K. Narayan

- R. K. Narayan, full name Rasipuram Krishnaswami Iyer Narayanaswami, was an Indian writer, best known for his works set in the fictional South Indian town of Malgudi.

- Born: October 10, 1906, Chennai

- Education: University of Mysore

- Siblings: R. K. Laxman

- Awards: Filmfare Award for Best Story, Padma Vibhushan, Padma Bhushan

R.K. Narayan

Author, Journalist (1906–2001)Indian author R.K. Narayan is widely considered to be one of India's greatest English language novelists known for his simple and unpretentious writing style.Synopsis

Indian author R.K. Narayan is widely considered to be one of India's greatest English language novelists known for his simple and unpretentious writing style, often compared to William Faulkner. Narayan has been nominated for the Nobel Prize in Literature multiple times but has not yet won the honor. His popular works include The English Teacher, The Financial Expert andWaiting for the Mahatma.

Sofcon Traning PVT LTD institute and company where Btech , Mtech, BSC and MSC students have became successful Automation Engineer in various field like PLC Training, PLC Scada Training, Embedded Training. Sofcon is not just a training provider, we are stand for help after job and Sofcon have placed 35000 thousand in automation industry. Sofcon Training Branches are available in all over Inida like Noida, Delhi, Lucknow, Gurgaon, Ahmedabad, Vadodara, Bhopal, Pune and Jaipur.

Friday 10 October 2014

R.K. Narayan Biography | Malgudi

Thursday 9 October 2014

Understanding The Programming Of The PLC

The programming of the plc is a procedure of making commands,

arrangements, and measurements used by the PLC to make control on a

machine or operation. The body of this process is the plc and the

program is the brain.In fact, the programmed PLC makes a machine looks

like a human. PLC stands for programmable logic controller.A PLC has

begun in the 1960's by Modicon Company.

Its initial application was in

the cars production factories in which it removed the old relays and

replaced it with the plc.

As usual, a better solution is always in a creative mind, though it was a

simple decision and control system effective for the era. Quickly, a

communication can be a mechanized switch operated by an electric supply

to switch it on and off.

Getting mechanized by nature is big compared to

electronic devices and transferring components usually degrade and

wear, and finally are unsuccessful. Producing the preferred relay common

sense needs many relays and many more wires in order to connect them.

Rewiring is needed if the logic is wrong or needs to be updated.

The PLC reduces many of these actual relays to create common sense which

moves and circuits them almost to the software. PLC development has

typically been and still at Step ladder Diagram or Step ladder Common

sense. It continues to be mostly employed language for encoding a PLC,

despite the fact that you will find choice spoken languages. The basic

reason is, it is rather like the electric powered schematics employed

for communicate reason.

Ladder reasoning is programmed using frequent power icons like those

utilized for contacts and coils. A step ladder diagram program appears

to be a power drawing that electricians are comfortable and familiar

with, very easy adoption from the difficult-wired relays for the PLC was

attained. Programming a PLC demands a certain knowledge and skill.

Comprehending the method that will be operated or programmed is

paramount. Start-up and Shutdown characteristics tend to be overlooked

or provided little focus at the start in which the concentration is in

the principal features of the machine or process. The PLC should be

picked to match the application as well as each one of the outputs and

inputs accounted for and extras integrated in the event that the task

expands or to deal with components that have been basically overlooked.

Planning upfront will save time and frustrations later, as with all

projects.

Getting together with all the stakeholders or those engaged might be a

wonderful initial step. Hash out the range and establish a time-range

and possess individuals included agreement to it. Later on, when extra

features or characteristics are asked for, you can support the

explanation of the coding task getting more than initially proposed.

PLC coding is only area of the whole job of automating a piece of

equipment. An expert must layout and stipulates the ingredients that

provide the PLC with its inputs and outputs that are going to control.

If you are only responsible to programming the plc, so you need all the

inputs and outputs lists and their specs from the engineer.

He or she will also be the main one to deliver a controlled narration or

information from the project. Undertaken one step more in advancement,

Boolean Reason diagrams might be provided to you the developer which can

(if in depth adequate) be used to create the program. Quite often the

Handles Electric Engineer will also carry out the programming and

perhaps the HMI coding... but which is another subject.

So in wrapping it up, PLC programming is about giving brains to machines

processes using a specialized computer and requires significant

knowledge and skills. I will tell you it can be a very fulfilling job

when it comes to struggle, constant studying, teamwork and last and

positively not very least, monetarily get.

Enhanced motion control, safety and performance

Kollmorgen Automation Suite version 2.8 delivers new functions

With

an embedded EtherCAT configuration tool, version 2.8 of the Kollmorgen

Automation Suite (KAS) software accelerates the development of modular

machine architectures.

The

new release of the integrated development environment now enables users

to build complete EtherCAT systems and configure all peripheral

components, including HMI, I/O, controllers and motors, with a single

tool. Along with ergonomic improvements, the resulting simplification

makes life easier for system developers and boosts engineering

efficiency.

One of the key innovations in Kollmorgen

Automation Suite 2.8 is the embedded EtherCAT configuration tool, which

makes it easy to integrate EtherCAT components (including those from

other manufacturers) into the application. With this open architecture,

Kollmorgen reduces development time for modular, multi-purpose machine

architectures. Another clear advantage of this approach is that direct

communication with Kollmorgen AKD PDMM servo controllers from PC-based

applications is now possible using UDP and HTTP protocols.

EtherCAT,

safety and visualisation: the new software release 2.8 of Kollmorgen

Automation Suite (KAS) offers a variety of new functions for faster

machine development.

Convenience

is also enhanced by the incorporation of safety technology in the

engineering process. For this purpose, the release integrates

Kollmorgen's new KSM series of safety modules. These compact devices

combine Safe PLC with Safe I/O in a single package and provide

TÜV-certified functions up to performance level e of ISO 13849 or SIL 3

of IEC 61508.

Version 2.8 of the Kollmorgen Automation

Suite also features performance enhancements for servo amplifiers. The

user-programmable controllers in the AKD PDMM family form the core of

KAS thanks to the "IPC inside" philosophy. Future devices feature twice

as much capacity at rated currents up to 24 A and faster processors.

Along with general performance enhancements, application options are

expanded by the inclusion of new motion control functions.

Wednesday 8 October 2014

PLC Programming Introduction | Sofcon

One method of the PLC programming is using ladder

diagram method. Ladder diagram consists of a descending line on the left, with

lines branching to the right. This line is the line branching instructions.

Throughout this instruction line consists a combination of logic that states

when and how the existing instructions on the right side are done.

Ladder Diagram Example

The logic

combination of ladder diagram as following:

A. Instruction

LOAD (LD) and LOAD NOT (LD NOT)

The

first condition that starts any logic block in the ladder diagram associated

with LOAD instruction (LD) or LOAD NOT (LD NOT). Each of these instructions

requires one line of mnemonic code.

B. Instruction

AND and AND NOT

If

two or more conditions that are connected in series on the same instruction

line, then the first condition using LD or LD instruction and the remainder NOT

use the instructions AND or AND NOT.

AND

instruction can be imagined to produce ON if both conditions are linked with

this instruction in all ON conditions, if any one in the OFF state, let alone

both OFF, the instruction will always result AND OFF too.

If two or more conditions connected in

parallel, meaning in a different line of instructions and then joined again in

the same instruction line, then the first condition associated with LD or LD

instruction and the rest is NOT related to the instructions OR or OR NOT.

In

this case imaginable OR instruction will always result in ON execution

condition when any one of two or more conditions connected with this

instruction in the ON condition.

Sofcon Arrange Workshope in RCEW ( Rajasthan College of Engineers for Women) Bhakrota, Jaipur....

The workshop was highly appreciated by 90 students of Electrical Branch ( II, III & Final Year Students). Feedback was positive.

Engineers detailed.

1. Mr. KL Swami ( Training Head)

2. Mr. Prem Kishan Rana (Automation Engineer)

3. Mr. Prithavraj (Embedded Engineer) Under Training

Tuesday 7 October 2014

PLC Real Time Clock Using Arduino programming at Sofcon

PLC real time clock using arduino and real time clock module. for real time module use DS3231 RTC Board. The way it works is: Arduino reads data from the DS3231, this data is sent directly to the PLC memory. and for setting the date and time via the DS3124 and computer by using visual basic net (VB.Net)

PLC real time clock process:

1. Read date and time from DS3231 RTC Board with Arduino via I2C communication

2. Send data to PLC with Arduino via RS232 communication and PLC Protocol

3. Receive data in PLC data memory

Flow process of the PLC Real TIme Clock:

Arduino Source Code#include <Wire.h>; const int DS1307 = 0x68; byte second = 0; byte minute = 0; byte hourofday = 0; byte dayofweek = 0; byte date = 0; byte month = 0; byte year = 0; byte set[7]; const char delimiter = ','; String message; byte i; int y; void setup() { Wire.begin(); Serial.begin(9600,SERIAL_8E1);//9600,8,Even,1 Serial.setTimeout(800); } void loop() { sendTime(); message = Serial.readString(); //= "year,month,date,week,hour,minute,second"; incomeTime(); } byte decToBcd(byte val) { return ((val/10*16) + (val%10)); } byte bcdToDec(byte val) { return ((val/16*10) + (val%16)); } void incomeTime() { i=0; y=-1; do { y = message.indexOf(delimiter); if(y != -1) { if(i<=5)set[i]=message.substring(0,y).toInt(); message = message.substring(y+1, message.length()); i++; } else { if(message.length() > 0 && i==6) set[i]=message.toInt(); } } while(y >=0); if (i==6){ if(set[0]>=0 && set[0]<=99){ if(set[1]>=1 && set[1]<=12){ if(set[2]>=1 && set[2]<=31){ if(set[3]>=1 && set[3]<=7){ if(set[4]>=0 && set[4]<=23){ if(set[5]>=0 && set[5]<=59){ if(set[6]>=0 && set[6]<=59){ setTime(); } } } } } } } } } void setTime() { year =set[0]; month =set[1]; date =set[2]; dayofweek =set[3]; hourofday =set[4]; minute =set[5]; second = set[6]; Wire.beginTransmission(DS1307); Wire.write(byte(0)); Wire.write(decToBcd(second)); Wire.write(decToBcd(minute)); Wire.write(decToBcd(hourofday)); Wire.write(decToBcd(dayofweek)); Wire.write(decToBcd(date)); Wire.write(decToBcd(month)); Wire.write(decToBcd(year)); Wire.write(byte(0)); Wire.endTransmission(); } void sendTime() { readTime(); int VB0 = second;// VB0=SECOND : 0 to 59 int VB1 = minute;//VB1=MINUTE : 0 to 59 int VB2 = hourofday;//VB2=HOUR OF DAY : 0 to 23 int VB3 = date;//VB3= DATE : 1 to 31 int VB4 = month;//VB4= MONTH : 1 to 12 int VB5 = dayofweek;//VB5= DAY OF WEEK : 1=SUNDAY, 2=MONDAY, 3=TUESDAY, 4=WEDNESDAY, 5=THURSDAY, 6=FRIDAY, 7=SATURDAY int VB6 = year;//VW6= YEAR 00 to 99 int VWstart = 0; //Start from VW0 int VWcount = 4; byte str_write[45]; long Temp_FCS=0; int i; str_write[1] = (byte)((VWcount * 2) + 31); str_write[2] = (byte)str_write[1]; str_write[24] = (byte)(VWcount * 2); str_write[16] = (byte)(str_write[24] + 4); str_write[33] = (byte)((VWcount * 16) / 256); str_write[34] = (byte)((VWcount * 16) % 256); str_write[29] = (byte)((VWstart * 8) / 256); str_write[30] = (byte)((VWstart * 8) % 256); str_write[0] = (byte)0x68;//H68 str_write[3] = (byte)0x68;//H68 str_write[4] = (byte)0x02;//H2 str_write[5] = (byte)0x00;//H0 str_write[6] = (byte)0x7C;//H7C str_write[7] = (byte)0x32;//H32 str_write[8] = (byte)0x01;//H1 str_write[9] = (byte)0x00;//H0 str_write[10] = (byte)0x0;//H0 str_write[11] = (byte)0x43;//H43 str_write[12] = (byte)0x01;//H1 str_write[13] = (byte)0x00;//H0 str_write[14] = (byte)0x0E;//HE str_write[15] = (byte)0x00;//H0 str_write[17] = (byte)0x05;//H5 str_write[18] = (byte)0x01;//H1 str_write[19] = (byte)0x12;//H12 str_write[20] = (byte)0x0A;//HA str_write[21] = (byte)0x10;//H10 str_write[22] = (byte)0x02;//H2 str_write[23] = (byte)0x00;//H0 str_write[25] = (byte)0x00;//H0 str_write[26] = (byte)0x01;//H1 str_write[27] = (byte)0x84;//H84 str_write[28] = (byte)0x00;//H0 str_write[31] = (byte)0x00;//H0 str_write[32] = (byte)0x04;//H4 str_write[35] = (byte)VB0; str_write[36] = (byte)VB1; str_write[37] = (byte)VB2; str_write[38] = (byte)VB3; str_write[39] = (byte)VB4; str_write[40] = (byte)VB5; str_write[41] = (byte)VB6; str_write[42] = (byte)0; for (i = 4; i <= 42; i++) { Temp_FCS = Temp_FCS + str_write[i]; } str_write[43] = (byte)(Temp_FCS % 256); str_write[44] = (byte)0x16;//H16 Serial.write(str_write, sizeof(str_write)); delay(100); byte str_val[6]; str_val[0] = (byte)0x10;//H10; str_val[1] = (byte)0x02;//H2; str_val[2] = (byte)0x00;//H0; str_val[3] = (byte)0x5C;//H5C; str_val[4] = (byte)0x5E;//H5E; str_val[5] = (byte)0x16;//H16; Serial.write(str_val, sizeof(str_val)); delay(100); } void readTime() { Wire.beginTransmission(DS1307); Wire.write(byte(0)); Wire.endTransmission(); Wire.requestFrom(DS1307, 7); second = bcdToDec(Wire.read()); minute = bcdToDec(Wire.read()); hourofday = bcdToDec(Wire.read()); dayofweek = bcdToDec(Wire.read()); date = bcdToDec(Wire.read()); month = bcdToDec(Wire.read()); year = bcdToDec(Wire.read()); }}

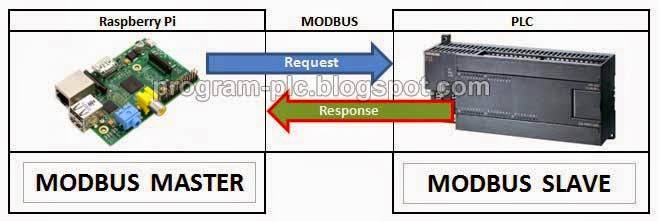

Modbus RTU Communication Between PLC and Raspberry Pi Using Python

Modbus communication in these applications using serial communication / RS232 and Modbus RTU.

This application use simple modbus with Python programming on Raspberry Pi, and not use modbus from a third party.

For the hardware used in this application:

1. PLC

2. Raspberry Pi (Only for setting, using: monitor, keyboard, mouse, adapter, flash disk)

3. Serial PLC Cable

4.Serial Module ,and

5. Serial Crossover Connector.

For the connection beetween PLC and Raspberry Pi, Raspberry Pi Setting (Auto Login, Install PySerial, Setup UART Pins, Auto Run Python after Booting) :

Connection of Modbus RTU Communication Between PLC and Raspberry Pi:

About Modbus:

Modbus application using function code 03, and function code 16. for this function code, you can go to the link:

http://program-plc.blogspot.com/2014/09/how-to-make-simple-modbus-rtu.html

Python Code of Modbus Communication on Raspberry Pi:

This application use simple modbus with Python programming on Raspberry Pi, and not use modbus from a third party.

For the hardware used in this application:

1. PLC

2. Raspberry Pi (Only for setting, using: monitor, keyboard, mouse, adapter, flash disk)

3. Serial PLC Cable

4.Serial Module ,and

5. Serial Crossover Connector.

For the connection beetween PLC and Raspberry Pi, Raspberry Pi Setting (Auto Login, Install PySerial, Setup UART Pins, Auto Run Python after Booting) :

Connection of Modbus RTU Communication Between PLC and Raspberry Pi:

About Modbus:

Modbus application using function code 03, and function code 16. for this function code, you can go to the link:

http://program-plc.blogspot.com/2014/09/how-to-make-simple-modbus-rtu.html

Python Code of Modbus Communication on Raspberry Pi:

import serial

import random

#Sub Program

#CRC

Calculation

def CRCcal(msg):

#CRC (Cyclical Redundancy Check)

Calculation

CRC = 0xFFFF

CRCHi = 0xFF

CRCLo = 0xFF

CRCLSB = 0x00

for i in range(0,

len(msg)-2,+1):

CRC = (CRC ^ msg[i])

for j in range(0,

8):

CRCLSB = (CRC & 0x0001);

CRC = ((CRC >> 1) &

0x7FFF)

if (CRCLSB == 1):

CRC = (CRC ^ 0xA001)

CRCHi = ((CRC >> 8) & 0xFF)

CRCLo = (CRC & 0xFF)

return (CRCLo,CRCHi)

#CRC Valdation

def CRCvalid(resp):

CRC = CRCcal(resp)

if (CRC[0]==resp[len(resp)-2])

& (CRC[1]==resp[len(resp)-1]):return True

return False

#Modbus

Function Code 16 = Preset Multiple Registers

def Func16Modbus(slave,start,values):

Slave_Address = slave

Function = 16

Starting_Address = start

NumberofRegisters = len(values)

Byte_Count = NumberofRegisters * 2

message = [0 for i in range(9 + 2 * NumberofRegisters)]

#index0 = Slave

Address

message[0] = (Slave_Address & 0xFF)

#index1 = Function

message[1] = (Function & 0xFF)

#index2 = Starting Address Hi

message[2] = ((Starting_Address >> 8)

& 0xFF)

#index3 = Starting Address Lo

message[3] = (Starting_Address & 0xFF)

#index4 = Number of Registers Hi

message[4] = ((NumberofRegisters >>

8) & 0xFF)

#index5 = Number of Registers Lo

message[5] = (NumberofRegisters & 0xFF)

#index6 = Byte Count

message[6] = (Byte_Count & 0xFF)

for i in range(0,

NumberofRegisters):

#Data Hi, index7 and index9

message[7 + 2 * i] = ((values[i]

>> 8) & 0xFF)

#Data Lo, index8 and index10

message[8 + 2 * i] = values[i] &

0xFF

#CRC (Cyclical

Redundancy Check) Calculation

CRC = CRCcal(message)

#index11= CRC Lo

message[len(message)

- 2] = CRC[0]#CRCLo

#index12 = CRC Hi

message[len(message)

- 1] = CRC[1]#CRCHi

if ser.isOpen:

ser.write("".join(chr(h)

for

h in

message))

reading = ser.read(8)

response = [0 for i in range(len(reading))]

for i in range(0,

len(reading)):

response[i] = ord(reading[i])

if len(response)==8:

CRCok = CRCvalid(response)

if CRCok &

(response[0]==slave) & (response[1]==Function):return True

return False

#Modbus

Function Code 03 = Read Holding Registers

def Func03Modbus(slave,start,NumOfPoints):

#Function 3 request is always 8 bytes

message = [0 for i in range(8)]

Slave_Address = slave

Function = 3

Starting_Address = start

Number_of_Points = NumOfPoints

#index0 = Slave

Address

message[0] = Slave_Address

#index1 = Function

message[1] = Function

#index2 = Starting Address Hi

message[2] = ((Starting_Address >>

8)& 0xFF)

#index3 = Starting Address Lo

message[3] = (Starting_Address& 0xFF)

#index4 = Number of Points Hi

message[4] = ((Number_of_Points >>

8)& 0xFF)

#index5 = Number of Points Lo

message[5] = (Number_of_Points& 0xFF)

#CRC (Cyclical Redundancy Check)

Calculation

CRC = CRCcal(message)

#index6= CRC Lo

message[len(message)

- 2] = CRC[0]#CRCLo

#index7 = CRC Hi

message[len(message)

- 1] = CRC[1]#CRCHi

if ser.isOpen:

ser.write("".join(chr(h)

for

h in message))

responseFunc3total = 5 + 2 *

Number_of_Points

reading = ser.read(responseFunc3total)

response = [0 for i in range(len(reading))]

for i in range(0,

len(reading)):

response[i] = ord(reading[i])

if len(response)==responseFunc3total:

CRCok = CRCvalid(response)

if CRCok &

(response[0]==slave) & (response[1]==Function):

#Byte Count in index 3 =

responseFunc3[2]

#Number of Registers = byte

count / 2 = responseFunc3[2] / 2

registers = ((response[2] /

2)& 0xFF)

values = [0 for i in

range(registers)]

for i in range(0, len(values)):

#Data Hi and Registers1

from Index3

values[i] = response[2 * i

+ 3]

#Move to Hi

values[i] <<= 8

#Data Lo and Registers1

from Index4

values[i] += response[2 * i

+ 4]

negatif =

values[i]>>15

if

negatif==1:values[i]=values[i]*-1

return values

return ()

#Main Program

#Serial Port

9600,8,E,1

#Serial Open

try:

ser = serial.Serial(

port = '/dev/ttyAMA0',

baudrate = 9600,

bytesize = serial.EIGHTBITS,

parity = serial.PARITY_EVEN,

stopbits = serial.STOPBITS_ONE,

timeout = 0.2

)

except Exception, e:

raise ValueError(e)

print "START"

while 1:

#Serial Open Check

if not ser.isOpen:ser.open()

#Read of Registers

Func03ArrayValue = Func03Modbus(1,0,2);#slave,start,number of registers

if len(Func03ArrayValue)>0:

for i in range(0,

len(Func03ArrayValue)):

print "Read of Registers" + str(i) + " = " + str(Func03ArrayValue[i])

#Fill Random Value for Write

totalvalue=2

val = [0 for i in range(totalvalue)]

for i in range(0,

len(val)):

val[i] = random.randrange(-32767,32767)

#Random Valiue from -32767 to max 32767

#Write of Registers

WriteValid =

Func16Modbus(1,2,val)#slave,start,array value

if WriteValid:

for i in range(0,

len(val)):

print "Write of Registers" + str(i) + " = " + str(val[i])

print "#################################"

Subscribe to:

Posts (Atom)